1.Waa maxay dhagaxa qadiimiga ah?

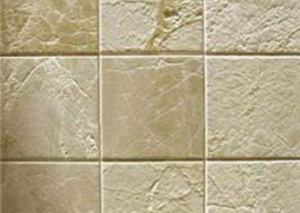

"Dhagaxa qadiimiga ah" waxaa loola jeedaa daaweynta gaarka ah ee granite dabiiciga ah ama marmar, si dusha sare ee dhagaxu uu leeyahay mowjado dabiici ah ama dildilaacyo la mid ah cimilada, isla markaana, saameynta dabiiciga ah ee dabiiciga ah ee dhagaxa ka dib isticmaalka muddada dheer ( matte qiyaas ah ama saamayn mercerized)).Guud ahaan, waa in lagu farsameeyo dhagaxa dabiiciga ah saameyn duug ah oo u eg in la isticmaalay boqollaal sano.

2. Faa'iidooyinka farsamaynta qadiimiga ah ee dhagaxa.

Habka qadiimiga ah ee dhagaxu wuxuu yeelan karaa saameyn aan sinnayn satin mercerizing, oo muujinaya dhaldhalaalka dabiiciga ah ee dhagaxa, iyo ciyaarista saamaynta qurxinta gaarka ah;Isla mar ahaantaana, waxay sidoo kale wanaajin kartaa ka hortagga iyo waxqabadka biyuhu ee dhagaxa, waxayna ciyaari kartaa saameyn liddi ku ah.Habaynta qadiimiga ah ee dhagaxu waxay sidoo kale ka fogaan kartaa wasakhowga iftiinka ee dhismayaasha sababtoo ah milicsiga gaarka ah ee iftiinka.Isla mar ahaantaana, dhagaxa qadiimiga ah waa sahlan tahay in la dayactiro ka dib xirashada.Isla mar ahaantaana, aberration chromatic ee midabku wuu ka yar yahay habka polishing, waxayna si fiican u muujin kartaa fikradda qiimaha ee ilaalinta deegaanka dabiiciga ah.

3.Alaabada ugu weyn ee abrasive ee farsamaynta qadiimiga ah ee dhagaxa dabiiciga ah.

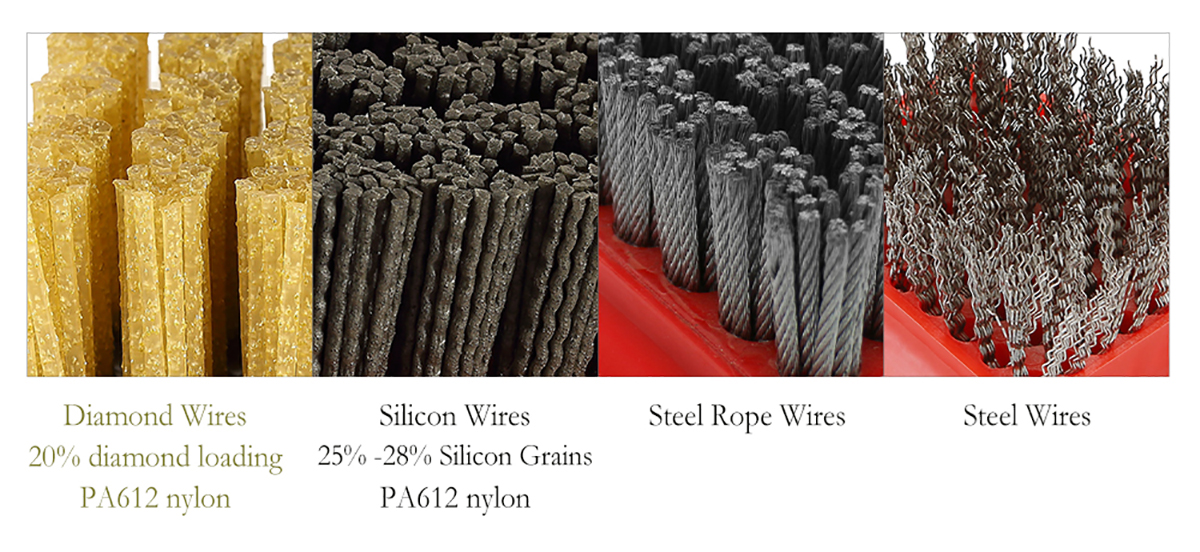

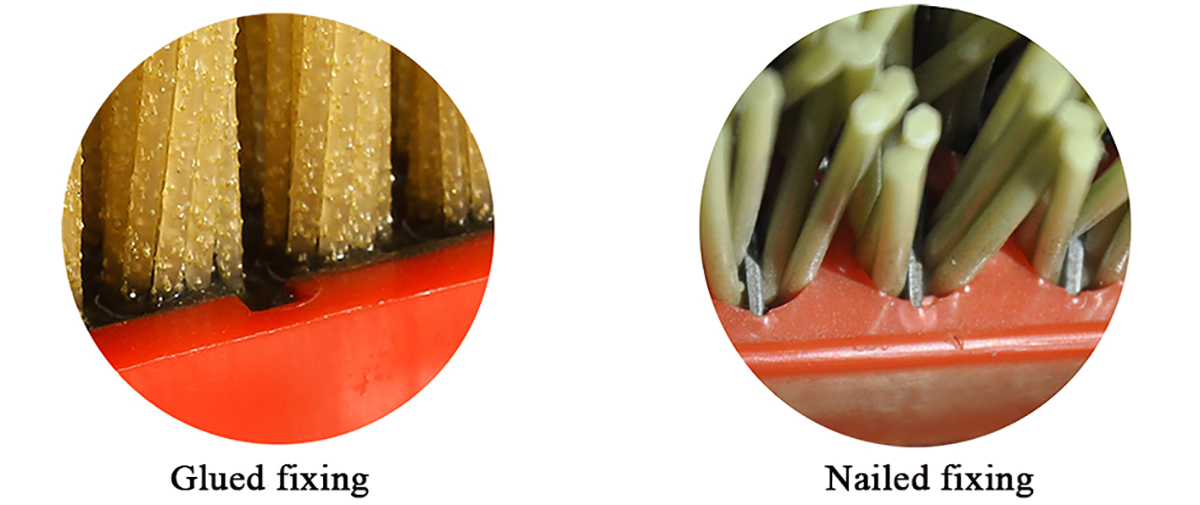

Buraashka abrasive waa qalabka ugu muhiimsan ee abrasive ee dusha qadiimiga ah, sida caadiga ah waxay ka samaysan yihiin 4 qalab fiilooyinka: dheeman, silikoon carbide, birta, xadhig birta ah. Markaas ku rakibidda fiilooyinka kuwaas oo galay caag ama alwaax, hagaajinta fiilooyinka by xabag ama biraha biraha ( hagaajinta ciddiyaha) .

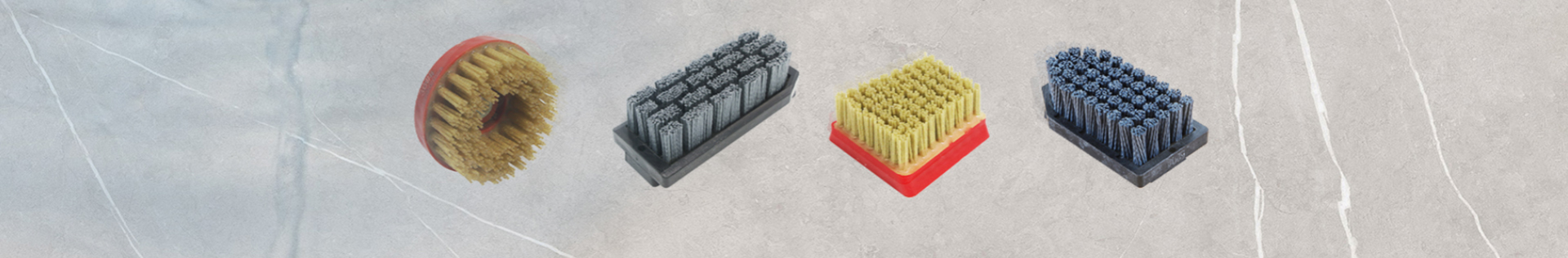

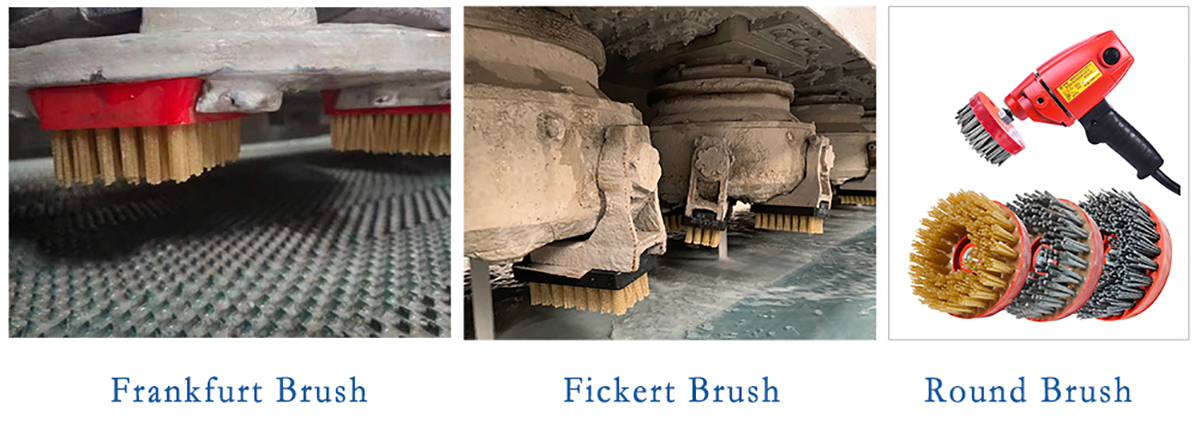

Waxaan u kala soocnay abrasive-ka 3 nooc iyadoo loo eegayo qaabab kala duwan iyo mashiinnada lagu dabaqi karo:burushka frankfurt, buraashka fickertiyo burush wareegsan.

Guud ahaan, burushka frankfurt waxaa loo isticmaalaa mishiinada wax lagu shiido gacanta, khadka si toos ah u silcin toos ah (loo sameeyo marmar, terrazzo), mishiinada dayactirka sagxada, iwm.

Buraashka wareega waxaa loo isticmaalaa mashiinnada suufka gacanta ee yaryar, mashiinnada dayactirka sagxadda;

Buraashka Fickert waxaa loo isticmaalaa mashiinnada wax shiida ee joogtada ah ee si toos ah loogu nadiifiyo granite ama dhoobada dhoobada ama quartz macmal ah.

4. Qulqulka farsamaynta ee dusha qadiimiga ah ee dhagaxa dabiiciga ah (tusaale granite).

Sababtoo ah qaabka adag ee granite, marka hore isticmaal dab ama biyo cadaadis sare leh si aad u farsamayso saxanka granite galay saxan dab ah oo qallafsan ama saxan qallafsan (sidoo kale waxaa lagu farsameyn karaa dusha ciid lychee, iwm., laakiin saameyntu maaha mid aad u badan). wanaagsan), dusha qallafsan waa inuu ka sii qallafsan yahay guddiga heesaha caadiga ah, si looga fogaado in looxa dhagaxa ah uu aad u siman yahay marka la isticmaalayo burushka dhagaxa ah ee tallaabada xigta, taas oo ka dhigi doonta qaabeynta luminaysa saameynteeda saddex-geesoodka ah.

Ka dib, marka loo eego shuruudaha gaarka ah ee macaamilka, isticmaal burushyada abrasive ee mesh aan dhab ahayn ilaa mesh ganaax si aad u shiiddo oo aad u nadiifiso si isdaba-joog ah ilaa dusha sare ee looxa uu gaaro saameynta loo baahan yahay iyo dhalaalid.Haddii macmiilku u baahan yahay si loo gaaro saameyn siman oo matte ah, waxay u baahan tahay oo kaliya inay isticmaasho burushka dheeman 36 # (ama 46 #), 60 # (ama 80 #), 120 # (ama 180 #) afar habraac;haddii ay tahay in la gaaro saamayn la mecerized, waxaad sidoo kale u baahan tahay inaad ku dartoburush carbide silicon240#, 320#, 400# saddex habsocod, dabcan, haddii dhammaan hababka la sameeyo, saamayntu way fiicnaan doontaa.

5. socodka processing ee dusha qadiimiga ah ee marmar dabiiciga ah

Sababtoo ah qalabka kala duwan iyo texture of marbles kala duwan, habka processing waa in lagu doortaa sida ay u kala duwan yihiin sifooyinka kala duwan oo kasta oo marmar ah.

Marble leh kaalshiyam badan iyo kaarboon magnesium ama dildilaacyo iyo daloolo ayaa lagu daxaleeyaa iyadoo lagu qooyay acid hydrochloric ilaa 10-20 daqiiqo (waxay kuxirantahay nooca dhagaxa gaarka ah);Intaa ka dib, isticmaal buraash bir ah si aad uga saarto hadhaaga dildilaaca iyo godadka si kor loogu qaado dusha dhagaxa.Ugu dambeyntii, isticmaal burushyada xoqan ee mesh aan dhab ahayn ilaa shabag khafiif ah si aad u shiiddo oo aad u nadiifiso si isku xigta ilaa dusha sare ee looxa uu gaaro dhalaalka uu u baahan yahay macaamilka.

Haddii ay tahay marmar leh calcite badan, waxaa si toos ah loogu farsamayn karaa burush bir ah.Waxa kale oo suurtogal ah in marka hore lagu cadaydo saamaynta saddex-geesoodka ah ee aan sinnayn ee buraash silig bir ah, ka dibna shiiddo oo si isdaba-joog ah u nadiifi burushka wax lagu shiida ee mesh aan caadi ahayn ilaa mesh ganaax ah, badanaa la isticmaalo 36# 60# 80# burush dheeman ah iyo 180 # , 240#, 320#, 400# burushka silikoonka ee farsamayntaHaddii ay tahay marmar adag, tallaabooyinkii hore ayaa si habboon loo kordhin karaa.

Fadlan xor u noqo inaad nala soo xidhiidho haddii aad danaynayso, waan ku faraxsanahay inaan ku caawinno.

Elain: +86-13336414847(Whatsapp / Wechat),email:expert01@huirui-c.com

Alice: +86-13336448141(Whatsapp / Wechat),email:expert02@huirui-c.com

Waqtiga boostada: Abriil-24-2023